TECHNICAL INFORMATION

The CO2 gas cylinder

The specific LBM CO2 gas cylinder for SHEV systems

Considering the specified features, specific CO2 gas cylinders have been developed for SHEV applications that ensure safe operation either at -20°C and at +110°C. The apparent density and the position of installation are of crucial importance here.

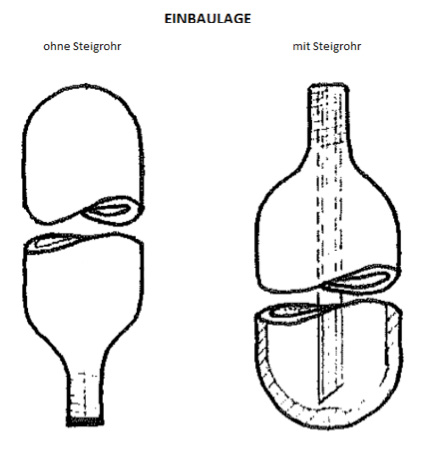

An “upside down” installation improves the escape of CO2. Where this not possible, the use of gas cylinders with ascending pipe will have the same effect. All LBM pressurised gas cylinders additionally feature a predetermined breaking point (bursting disc) enabling the gas, in case of need, to escape into the system.

An “upside down” installation improves the escape of CO2. Where this not possible, the use of gas cylinders with ascending pipe will have the same effect. All LBM pressurised gas cylinders additionally feature a predetermined breaking point (bursting disc) enabling the gas, in case of need, to escape into the system.

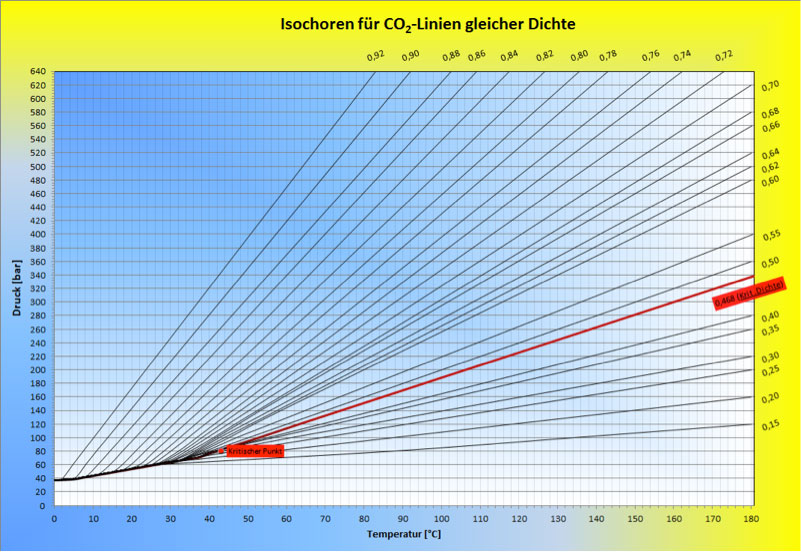

Quantity of gas / unit volume / operating pressure / temperature

A precise quantity calculation is very complicated, so let us provide just a few basic details: Approx. 2g CO2 are approx. 1l expanded gas. If a CO2 gas cylinder with a volume of 20g is triggered at ambient temperature, in terms of figures, a working pressure of 10 bar is built up. After triggering, the system cools down a little bit, so that the final pressure is not immediately achieved. The operating pressure decreases at lower temperatures and considerably increases at higher temperatures.

Downloads

Certificates

ISO 9001 german

ISO 9001 englisch

ISO 14001 german

ISO 14001 englisch

In-house inspection service

Supervision of manufacture